Stretch breaking converting

our partners

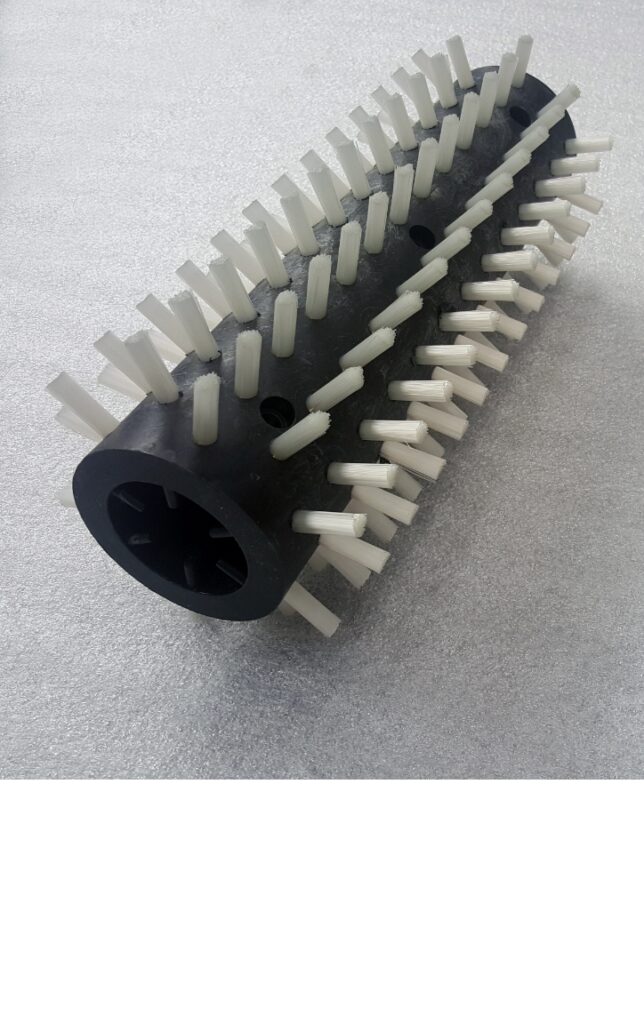

Original and High-Quality Spare Parts for N. Schlumberger Machines

Tarris Kavir can provide all original and high-quality spare parts for N. Schlumberger machines., we ensure that your equipment remains in optimal condition and continues to perform at its best.

The various n. schlumberger cards are designed to process natural fibres like wool or mohair, as well as synthetic fibres, silk noil or flax tows.

Worsted card

Designed to process wool and other natural fibres such as mohair with two morels cylinders for the processing of scoured wool.

Semi-worsted card

Suited to the processing of both natural and synthetic fibres. The semi-worsted card can be incorporated into any semi-worsted process line for carpet or knitting yarns.

Flax card

This card is tailored to the process of flax tow and bast fibres. It is provided with a bale opener, especially suited to the bast fibres. This card is only available in 2.5 m working width.

Feeder

The continuous flow volumetric feeder determines the uniform distribution of fibres. It is achieved by high precision machines which accurately monitor the fibre control.

To complement their high performance feed systems and particularly on small batches with short manufacturing cycles, the cards can be supplied on optional with an infeed autoleveller.

S200

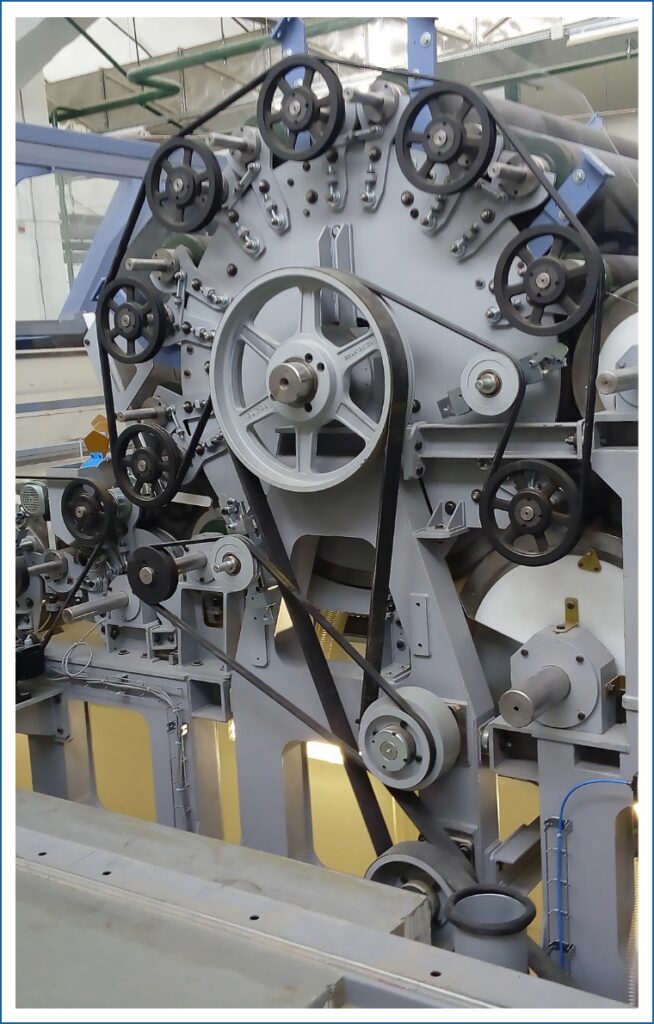

Stretch breaking converting

The S200 stretch breaker processes chemical filament tows into wool-like slivers for knitting and hosiery yarns. It handles acrylic, polyester, polypropylene, and viscose fibers.

Key features include:

Robust, reliable, and precise structure

Easy servicing and adjustments

Full safety coverage

Modular design with heating plates and suction systems

Crimping box and compact steaming system

Handles up to two tows with overload safety

Touch screen control panel

Speeds up to 400 m/min

The FB20 model, ideal for technical fibers like flax and carbon, uses a short in-line breaking process with pre-stretching and three breaking heads

D5GC40

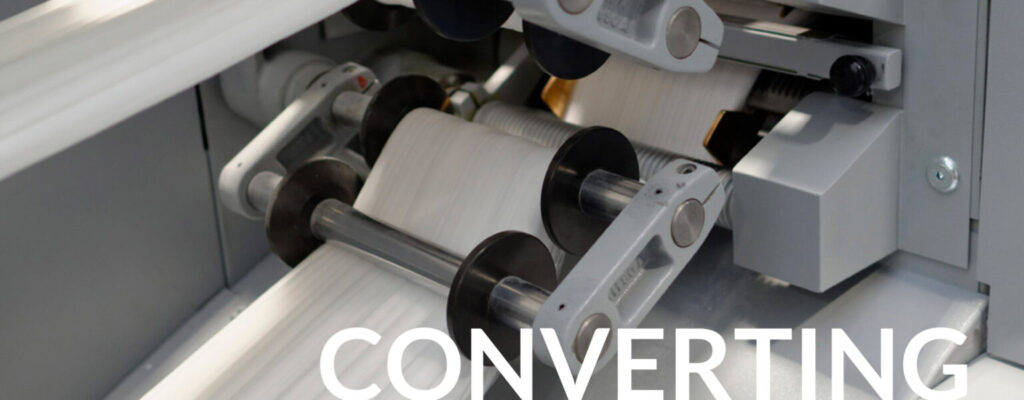

The homogeneity and evenness of the sliver

The D5GC40 blender defelter, ideal for post-stretch breaking, features a pre-draft element with 4 drafting zones and a GC40 chain gill. It suits Tow To Top lines, blending, and defelting operations, particularly for fine fibers.

Key features include:

Handles 100% relaxed or High Bulk blends

Suitable for grey, dyed, spun-dyed, or tow-dyed slivers

High doubling up to 40 slivers

Input load up to 2 x 500 ktex

Efficient suction system

Optional spraying devices and draft autoleveller

GC50

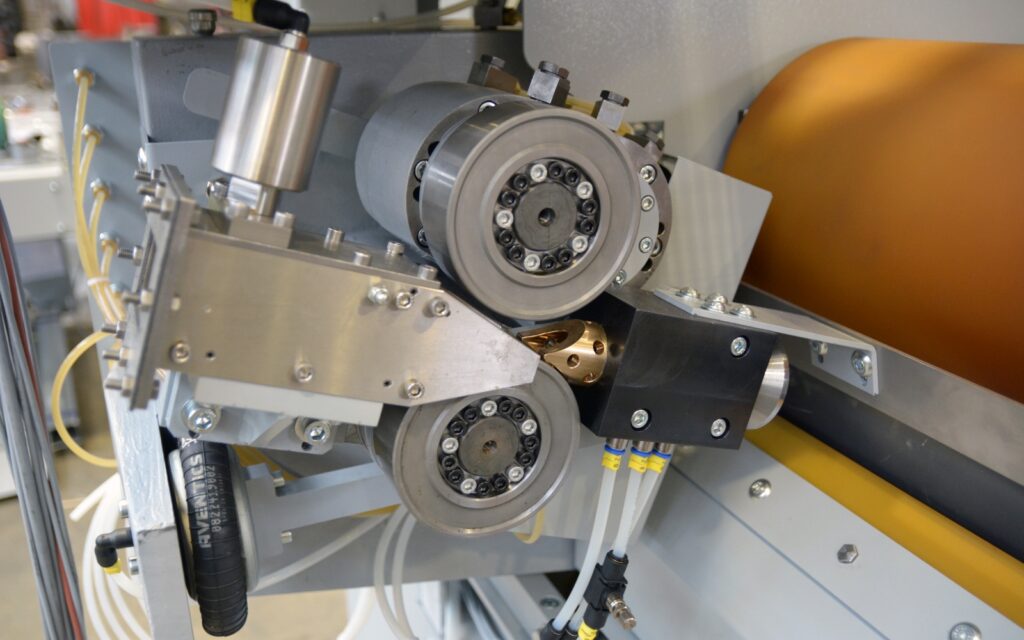

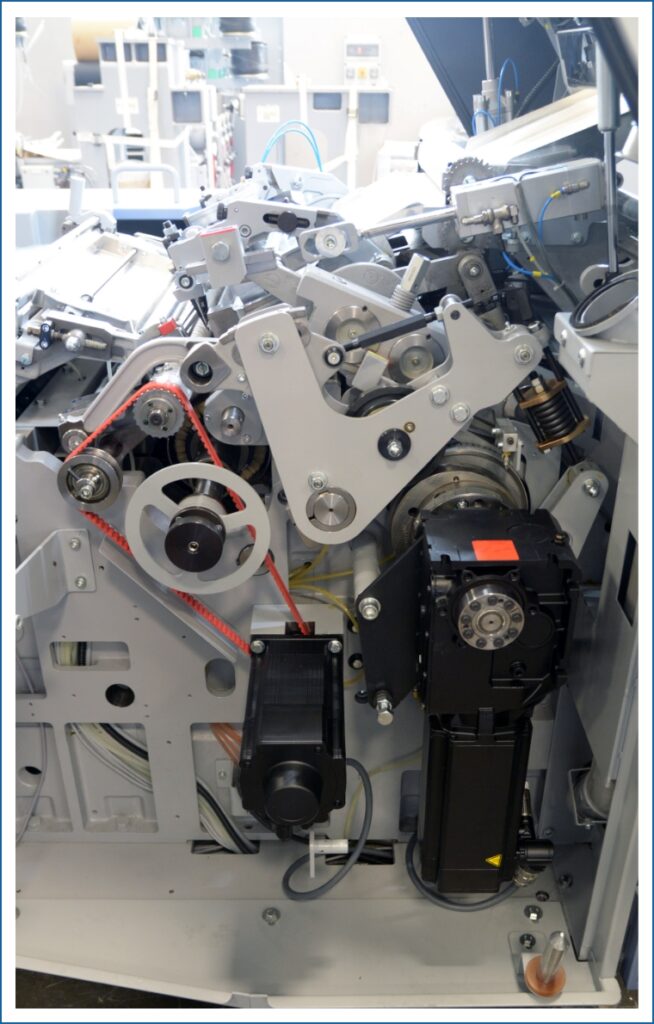

The mechatronic chain gill

The GC50 chain gill utilizes advanced mechatronic technology for easier use and maintenance, reducing mechanical settings and operator interventions. Key features include:

Electronic control of nip distance and tensions for precision

Larger filter bags for improved cleaning and adjustable suction power

15” control screen displaying real-time data and machine documentation

Fewer mechanical parts for reduced maintenance

Industry 4.0 readiness with comprehensive data collection

These innovations enhance reliability, precision, and textile quality during production.

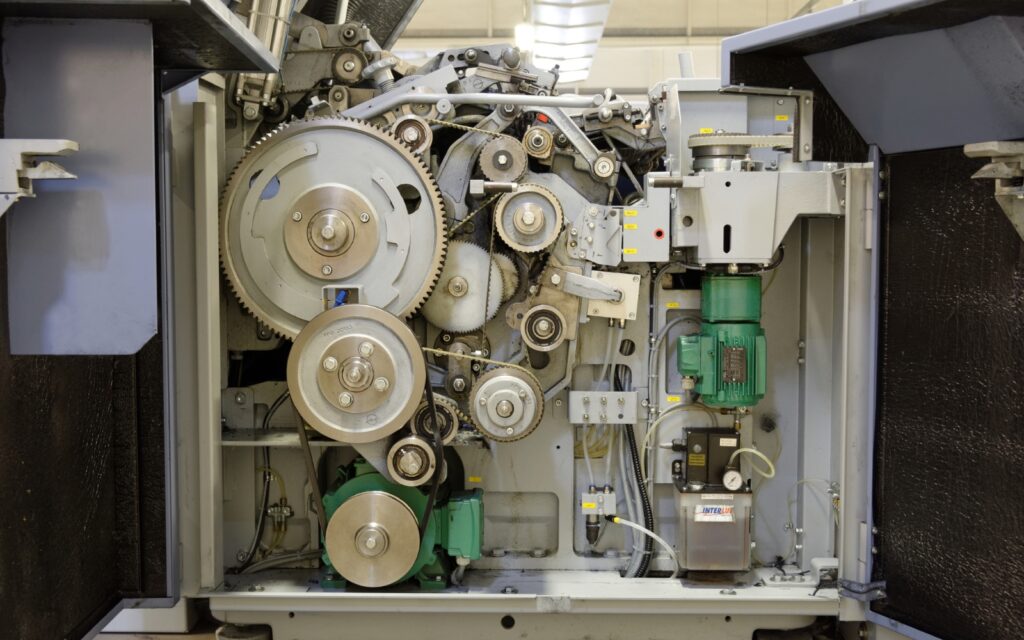

ERA50

The new standard in wool cleanliness

The ERA50, an upgrade from the ERA40, incorporates mechatronic technology and is Industry 4.0 ready with complete data collection. Key features include:

Electronic control of 9 axes for precise settings and improved textile quality

Optimized cleanliness with 4 comb speeds and larger filtering bags

15” touch screen displaying real-time production data, documentation, and power consumption

Internet connectivity for remote diagnostics

These innovations ensure a cleaner, more efficient combing process, enhancing textile quality and reducing maintenance.

FMV50

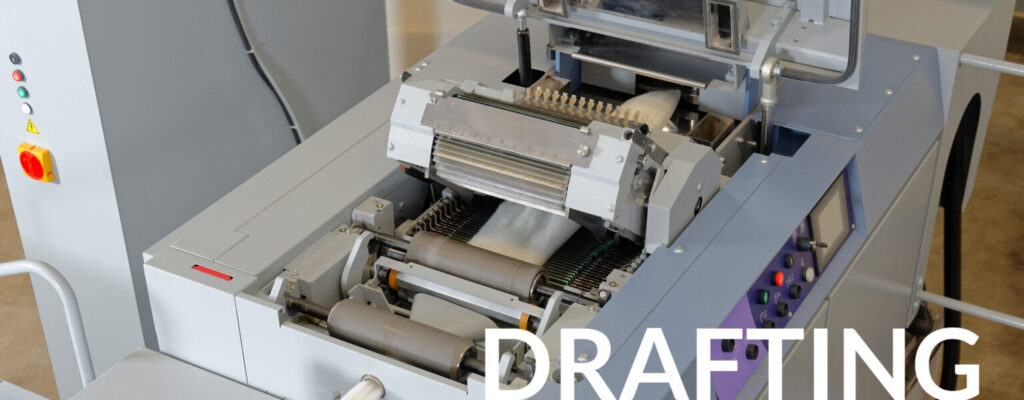

The mechatronic vertical rubbing frame

The FMV50, an upgrade from the FMV40, incorporates mechatronic technology and is Industry 4.0 ready with full data collection and remote diagnostics. Key features include:

Electronic monitoring for reduced mechanical settings and operator interventions

Models: FMV50S (300 mm tubes, up to 4.5 kg) and FMV50L (330 mm tubes, 5-6 kg)

Produces rubbed rovings (Nm 0.66 to 6) at speeds up to 275 m/min

Three interchangeable drafting systems (long and short with aprons)

Adjustable rubs from 2.5 to 10 rubs/m electronically, up to 1500 rubs/min

Additional innovations:

New suction system with dual filtering bags for easier cleaning and better durability

15” touch screen for real-time data, machine documentation, and power consumption information

These features ensure high performance, flexibility, and efficiency in modern production lines.

We offer a comprehensive range of original spare parts for all N. Schlumberger machines, ensuring optimal performance and longevity. Our genuine parts are designed to maintain the high standards of quality and reliability you expect from N. Schlumberger equipment.

We eagerly look forward to hearing from you and are committed to building a successful partnership to achieve shared goals in the textile manufacturing industry.